Have you ever wondered how that seemingly random string of numbers and lines on your favorite product magically translates to everything you see on the store shelf – price, origin, and even nutritional information? Those lines are actually a barcode, a visual representation of a Universal Product Code (UPC).

Think of a UPC as your product’s unique fingerprint in the world of commerce. It allows retailers and manufacturers to effortlessly track your product throughout its journey, from the factory floor to the checkout counter. But how exactly do you get one of these essential codes for your own brand?

There are two main options to obtain a UPC:

GS1 (Global Standards One): As the official organization responsible for issuing UPCs, GS1 acts as the central hub for product identification. By becoming a member of GS1, you gain access to a pool of unique UPC codes that you can then assign to your products. This membership does come with associated fees, so it’s important to consider the volume of products you need to code.

Authorized Resellers: Several third-party companies act as authorized resellers of GS1-issued UPCs. These resellers often offer additional services alongside the codes, such as barcode image generation or assistance with product registration. While convenient, these services may come at an additional cost compared to going directly through GS1.

In the next section, we’ll dive deeper into the world of barcodes and how they translate those UPCs into a scannable format. We’ll also explore the power of QR codes and how they can take your product communication a step further!

Understanding Barcodes: Decoding the Stripes

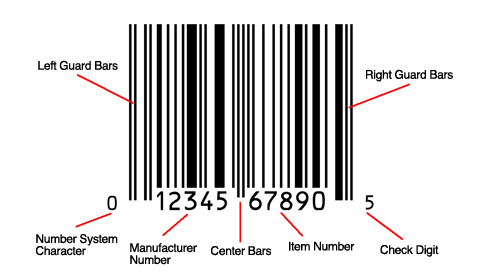

Now that you know how to secure a UPC, let’s explore how it transforms into the familiar barcode we see on countless products. Think of a barcode as a translator, taking the numerical UPC and converting it into a series of lines and spaces that scanners can easily interpret.

There are actually different types of barcodes, each suited to specific needs. The most common for retail products in the US is the UPC-A, which can encode 12 digits. For smaller packages with limited space, a more compact UPC-E might be used.

Generating Your Barcode Image: Putting the Code on Display

So, you have your UPC and understand the concept of barcodes, but how do you get that visual representation onto your packaging design? Here are a few options:

- Online Barcode Generators: While tempting for their convenience, free online barcode generators often come with limitations. The generated images might be low quality, unsuitable for printing, or even contain hidden data.

- Barcode Creation Software: Some UPC providers offer dedicated barcode creation software. This ensures high-quality, scannable codes, but requires additional software purchase.

- Primeflex Services: Here at Primeflex, we understand the importance of clear and accurate barcodes on your product labels. We offer high-quality barcode image generation services, ensuring your codes scan flawlessly at checkout.

The Power of QR Codes: Beyond the Barcode

While barcodes excel at product identification, QR codes (Quick Response codes) offer a whole new level of engagement. These square, checkered patterns can encode a variety of data, not just website URLs.

Imagine including a QR code on your label that takes customers directly to a dedicated product information page. They can see detailed descriptions, usage instructions, or even access exclusive promotions. QR codes can also link to interactive experiences like instructional videos or fun games, fostering a deeper connection with your brand.

Primeflex: Your Partner in Product Identification

At Primeflex, we’re passionate about helping businesses bring their products to life. We offer a comprehensive range of services to ensure your product labels are not only visually stunning but also functionally perfect. From choosing the right UPC and barcode format to generating high-quality barcode images and seamlessly integrating QR codes into your packaging design, our team of experts is here to guide you every step of the way.

UPCs, barcodes, and QR codes play a crucial role in the world of product identification and communication. By understanding these systems and utilizing them effectively, you can ensure your products stand out on store shelves and connect with your customers on a deeper level.

Ready to unlock the power of product codes for your brand? Contact Primeflex today for a consultation on your specific labeling needs. We’ll help you choose the right solutions and navigate the process seamlessly, so you can focus on what matters most – creating exceptional products.